Understanding Ventilated Chemical Storage Cabinets

In the bustling world of labs and factories, chemicals are the lifeblood of innovation and progress. But, these potent substances come with a hidden danger: harmful fumes and vapors. This is where ventilated chemical storage cabinets step in, acting as the silent guardians of safety, protecting both people and the environment.

Design Features for Effective Fume Control

Ventilated chemical storage cabinets are meticulously designed to control the release of hazardous fumes and vapors. They employ a combination of features to ensure that these dangerous substances are contained and safely exhausted.

- Exhaust Fans: These powerful fans work tirelessly to draw out fumes and vapors from the cabinet, preventing them from accumulating and posing a risk. The exhaust system is usually connected to a duct that leads to the outside, ensuring that the contaminated air is safely discharged away from the workspace.

- Air Filtration Systems: Some cabinets are equipped with air filtration systems that act as a secondary line of defense. These systems use filters to trap and remove harmful particles and gases from the air before it is released back into the environment. This is especially crucial for handling chemicals that release volatile organic compounds (VOCs) or other toxic substances.

- Cabinet Construction: The cabinet itself is constructed using materials that are resistant to chemical corrosion and leakage. This ensures that the cabinet remains structurally sound and does not become a source of contamination. The doors and seals are also designed to provide a tight fit, minimizing the risk of fumes escaping.

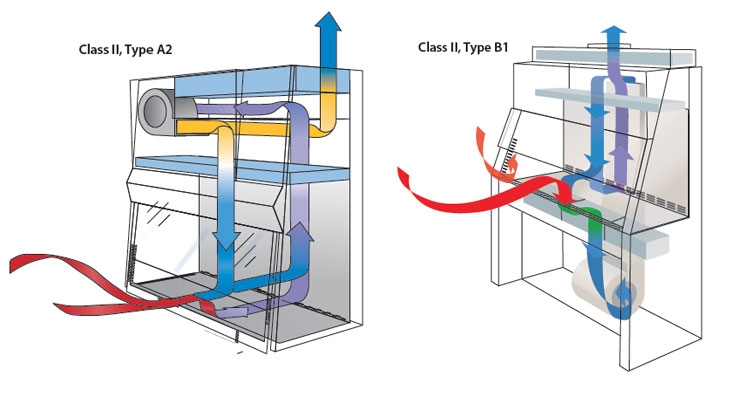

Types of Ventilation Systems

Ventilated chemical storage cabinets employ different types of ventilation systems to effectively control the release of hazardous fumes and vapors. The choice of system depends on the specific chemicals being stored and the level of risk involved.

- Exhaust Fans: These are the most common type of ventilation system used in chemical storage cabinets. Exhaust fans create a negative pressure inside the cabinet, drawing in air from the surrounding environment and expelling it through a duct system. The exhaust system is typically vented to the outside, ensuring that the contaminated air is safely discharged away from the workspace.

- Air Filtration Systems: Air filtration systems are used in conjunction with exhaust fans to further enhance fume control. These systems use filters to trap and remove harmful particles and gases from the air before it is released back into the environment. Different types of filters are available, including activated carbon filters, HEPA filters, and chemical-specific filters, each designed to target specific types of contaminants.

- Combination Systems: Some cabinets employ a combination of exhaust fans and air filtration systems to provide the highest level of fume control. This approach ensures that even the most hazardous chemicals are effectively contained and safely exhausted.

Safety Considerations for Chemical Storage

Storing chemicals safely is crucial for any workplace, especially when dealing with hazardous substances. It’s not just about keeping things tidy; it’s about preventing accidents, protecting employees, and ensuring compliance with regulations. This section dives into the essential safety considerations for chemical storage and the role of ventilated chemical storage cabinets in achieving these goals.

Key Safety Regulations and Standards

Understanding the regulations and standards governing chemical storage is vital. They provide a framework for safe handling and storage practices, minimizing risks to workers and the environment.

- Occupational Safety and Health Administration (OSHA): This agency sets standards for workplace safety, including chemical storage. OSHA’s Hazard Communication Standard (HCS) mandates the use of Safety Data Sheets (SDSs) and labeling for hazardous chemicals, providing essential information for safe handling and storage.

- National Fire Protection Association (NFPA): NFPA provides fire safety standards, including those related to chemical storage. NFPA 704, the “Diamond System,” is widely used for hazard labeling and communication, providing a quick visual assessment of the risks associated with a particular chemical.

- Environmental Protection Agency (EPA): The EPA plays a role in regulating the storage and disposal of hazardous chemicals, particularly those impacting the environment. Their regulations cover aspects like spill prevention and control, waste management, and proper disposal.

Role of Ventilated Chemical Storage Cabinets

Ventilated chemical storage cabinets are designed to protect workers and the environment by ensuring the safe storage of hazardous chemicals. They offer several key advantages:

- Containment: These cabinets are built to contain spills and leaks, preventing the spread of hazardous chemicals. This minimizes exposure risks and protects the workplace from contamination.

- Ventilation: The ventilation system in these cabinets removes harmful fumes and vapors, reducing the risk of exposure to workers and improving air quality within the storage area. This is particularly important for volatile chemicals that release vapors over time.

- Fire Resistance: Some ventilated cabinets are fire-resistant, providing an additional layer of safety in case of a fire. They can help contain the fire and prevent it from spreading to other areas, minimizing damage and protecting personnel.

- Compliance: Using ventilated chemical storage cabinets demonstrates a commitment to workplace safety and compliance with regulations. They help ensure that chemicals are stored properly, minimizing risks and meeting legal requirements.

Selecting the Right Ventilated Chemical Storage Cabinet

Choosing the right ventilated chemical storage cabinet depends on the specific chemicals being stored and the requirements of your workplace.

- Type of Chemicals: The type of chemicals being stored will determine the cabinet’s requirements. For example, flammable liquids require cabinets with a specific fire rating, while corrosive chemicals may require special materials to resist damage.

- Quantity of Chemicals: The amount of chemicals stored will influence the size and capacity of the cabinet needed. Consider the volume of each chemical and the total storage space required.

- Ventilation Requirements: The ventilation system should be adequate for the chemicals being stored. Some cabinets have adjustable ventilation rates to accommodate different chemical properties and storage needs.

- Safety Features: Look for features like spill containment trays, fire suppression systems, and alarms to enhance safety and provide additional protection.

Applications and Examples: Ventilated Chemical Storage Cabinet

Ventilated chemical storage cabinets are crucial in various settings where chemicals are handled. These cabinets offer a safe and controlled environment for storing a wide range of chemicals, protecting both personnel and the environment.

Industries and Laboratories

Ventilated chemical storage cabinets are essential in a variety of industries and laboratories where chemicals are regularly used.

- Pharmaceutical Industry: Manufacturing and research facilities require safe storage for active pharmaceutical ingredients (APIs), solvents, and other chemicals used in drug development and production.

- Chemical Manufacturing: Chemical plants utilize these cabinets to store raw materials, intermediates, and finished products, ensuring safety during handling and transportation.

- Research Laboratories: Academic and industrial research labs rely on ventilated cabinets to store a wide range of chemicals, including reagents, solvents, and hazardous materials used in experiments.

- Healthcare Facilities: Hospitals, clinics, and other healthcare settings use ventilated cabinets for storing disinfectants, cleaning agents, and other chemicals used in patient care.

- Educational Institutions: High schools, colleges, and universities utilize these cabinets to store chemicals used in science labs and educational demonstrations.

Storage of Specific Chemical Types

Ventilated chemical storage cabinets are designed to accommodate different types of chemicals based on their hazards and properties. Here are some examples:

- Flammable Liquids: These cabinets are often equipped with flame-resistant materials and ventilation systems to prevent the accumulation of flammable vapors. Examples include gasoline, acetone, and ethanol.

- Corrosive Materials: Cabinets designed for corrosive materials are typically constructed from corrosion-resistant materials like stainless steel or epoxy-coated steel. Examples include acids (e.g., hydrochloric acid, sulfuric acid), bases (e.g., sodium hydroxide), and solvents (e.g., toluene, xylene).

- Reactive Chemicals: Cabinets for reactive chemicals are designed to minimize the risk of accidental reactions. They may feature specialized ventilation systems and safety features to prevent the release of hazardous fumes or gases. Examples include strong oxidizers (e.g., potassium permanganate), reducing agents (e.g., sodium borohydride), and highly reactive metals (e.g., lithium, sodium).

Types of Chemical Storage Cabinets and Applications

| Type of Cabinet | Typical Applications |

|---|---|

| Flammable Liquid Storage Cabinet | Storage of flammable liquids like gasoline, acetone, and ethanol. |

| Corrosive Material Storage Cabinet | Storage of acids, bases, and solvents like hydrochloric acid, sulfuric acid, sodium hydroxide, toluene, and xylene. |

| Reactive Chemical Storage Cabinet | Storage of strong oxidizers, reducing agents, and highly reactive metals like potassium permanganate, sodium borohydride, lithium, and sodium. |

| General Purpose Chemical Storage Cabinet | Storage of a variety of chemicals that do not require specialized features, such as non-hazardous materials and reagents. |

Ventilated chemical storage cabinets are essential for maintaining a safe and compliant laboratory environment. They provide a secure and controlled space for storing hazardous materials, ensuring proper ventilation to mitigate the risk of explosions or toxic fumes. Similar to the importance of secure storage in laboratories, maintaining the safety of firearms is equally crucial.

A well-designed in wall gun storage cabinet can offer peace of mind and prevent unauthorized access. Returning to the topic of chemical storage, proper ventilation in these cabinets is vital to prevent the buildup of flammable or toxic vapors, protecting both personnel and the environment.

Ventilated chemical storage cabinets are essential for safely storing hazardous materials, ensuring proper ventilation to prevent the accumulation of flammable vapors. For non-hazardous items, however, the ClosetMaid Jumbo Storage Cabinet offers a robust and spacious solution. This type of cabinet, while not designed for chemicals, can provide an organized and efficient storage solution for various household items, allowing you to focus on the proper containment of hazardous materials in specialized cabinets.